Have any Question ? Call Us : +971 50 651 0922

Cold cutting of steel pipelines & tanks

Hydro flow is one of the market leader in the GCC and MENA region when it comes to cold cutting, we have several standard cold cutting systems in our group and we are able to offer customized cutting systems to our clients to handle the most complex of projects.

Our cold cutting systems have been utilized for many cold cutting operations in the Oil and Gas, shipping, process industries and the construction industry. Hydroflow have completed many cold cutting projects in the Middle East area with projects undertaken for disinvestments of pipelines, tanks and vessels. Cold cutting techniques have been widely used by Hydroflow due to its Safe method of operation for work undertaken where gases, oil carbons or flammables are still present in the work area.

The method of using High pressure water with entrained abrasives has been around for many years, having been introduced and demonstrated in the UK in the early eighties. The use of cold cutting is paramount in a variety of situations including but not limited to Oil well re-establishment.

In the Iraq – Kuwait war in the early nineties, many oil fires at the well heads, once extinguished, required new Blow out Prevention systems (BOP’s) to be repaired or cut off at the caisson level below the damaged area. These BOP’s were cut predominantly with High pressure water and abrasives. Cold cutting can be carried out in most areas of any situation whereby the danger of fire and explosion is to be considered.

Once identified by Safety Depts. as a high risk operation whilst attempting to cut steel using flame or heat creating equipment, we can now operate these projects with far less risk, utilizing less manpower and in a controlled environment.

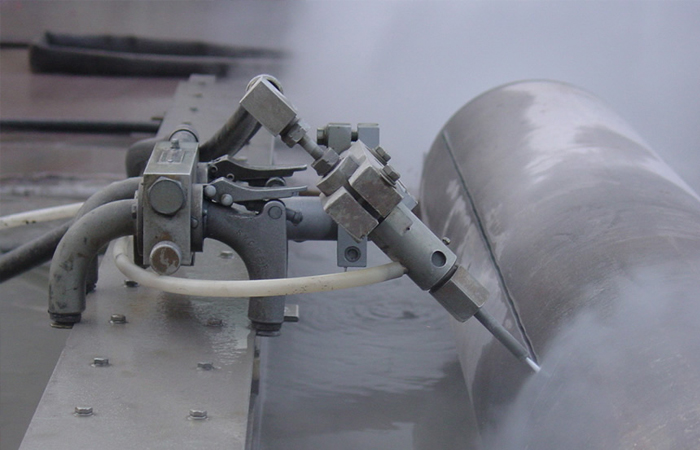

Hydroflow utilize their high pressure pump units in excessive of 30,000 psi in most cold cutting activities, with the use of the High pressure of the water directed at the steel surface with a quantity of metered abrasive (which is entrained in the water jet stream) allows us to cut through steel of various thicknesses.

The high pressure water jet and abrasive are utilized in a controlled manner whereby the cutting head is mounted on a variety of manipulators which travel at a controlled speed along the cutting surface and the thicker the steel the slower the speed to obtain a clean cut through and through.

In cases where Reactor vessels are to be cut, we have to cut through the outer steel shell and the internal steel mesh and cement material in a single pass. The speed and flow is all important to ensure the variable materials are cut through.

Concrete slabs and beams are also cut using the Cold cutting method. This enables a controlled demolition of concrete.

The concrete and the reinforcing steel need to be cut through from top to bottom and slabs as thick as 1m have been cut by Hydroflow using the cold cutting method.